Difference between revisions of "Financial control"

(Created page with "Test création") |

(init) |

||

| Line 1: | Line 1: | ||

| − | + | The key factors of profitability are managing your income and controlling and forecasting expenses. Therefore, having a good financial control of your project is necessary. It is then recommended to have a cost controller on the project who will monitor de performance of the project and provide the economic and financial indicators to analyze the operational and strategic management of the project. | |

| + | |||

| + | == Role of Financial control == | ||

| + | Among other things, Financial control main missions are to : | ||

| + | |||

| + | * Monitor project costs and check whether the established objectives have been reached, highlighting any differences with respect to forecasts and identifying, if so, the causes of such deviations, and implementing corrective actions | ||

| + | * Carrie out the reviews of the end-of-site forecasts; | ||

| + | * Performs risk analysis; | ||

| + | * Perform cash analysis and cash forecasts | ||

| + | * Prepare monthly reporting | ||

| + | |||

| + | == Steps of Financial control == | ||

| + | In order to produce the best monitoring, the cost controller must first: | ||

| + | |||

| + | * Read carefully the contract (terms of payment, penalties, bank guarantees, insurances, etc.) | ||

| + | * Understand the milestones and establish a cash-in follow up that will be revised monthly with the operational staff | ||

| + | * Establish a client invoicing follow-up | ||

| + | * Establish a bank guarantee follow-up | ||

| + | * Establish an insurance follow-up | ||

| + | * Understand perfectly the budget allowed to the project and set up a detailed budget breakdown with cost codes (cf '''''Cost Codes''''' section) | ||

| + | * Create processes for Purchase Orders and a subcontractor follow-up (cf '''''Purchase Requisition Procedure''''' section) | ||

| + | * Create a monthly monitoring framework (cf '''''Topsheet''''' section) | ||

| + | |||

| + | === '''''Budget Breakdown and Monthly Reporting''''' === | ||

| + | The production team responsible for the project is committed to forecasting end-of-work expenses that we can call the Objective. The Objective is an intangible reference which represents the common commitment of the production. Every month, the cost controller will compare the reality of expenditure to this initial forecast and present it on a topsheet. This reporting will make it possible to: | ||

| + | |||

| + | * Know the results at the stage and at the end of the work, | ||

| + | * Compare achievements with forecasts, | ||

| + | * Appreciate the future trajectory by assessing the obstacles and risks, | ||

| + | * Decide on actions to influence the trajectory in order to achieve / improve the objectives set | ||

| + | |||

| + | ==== '''''Cost Codes''''' ==== | ||

| + | Once he possesses the budget breakdown, the cost controller needs to allocate each category of costs with an analytical code that will help him to allocate all the costs in front of the right budget. The breakdown can be more or less precise, depending on the level of cost analysis desired. An example of the breakdown is given on the right: | ||

| + | [[File:Cost codes.png|thumb|Cost code example]] | ||

| + | |||

| + | |||

| + | ==== '''''Topsheet''''' ==== | ||

| + | The topsheet is the main document of the monthly reporting = it synthetizes the results at the stage and at the end of the works and compares it with the budget. | ||

| + | |||

| + | It gathers all the costs, here is an example of a topsheet for the follow up of a solar project: | ||

| + | [[File:Topsheet.png|center|thumb|532x532px|Topsheet example]] | ||

| + | |||

| + | ==== '''''Purchase Requisition Procedure''''' ==== | ||

| + | |||

| + | ===== Overall Process Summary ===== | ||

| + | [[File:PR process.png|center|thumb|605x605px]] | ||

| + | |||

| + | ===== Example of a Purchase Requisition Form ===== | ||

| + | [[File:PR template.png|center|thumb|471x471px]] | ||

| + | |||

| + | |||

| + | Tracking Follow up Example | ||

| + | [[File:PR tracker.png|center|thumb|454x454px]] | ||

| + | |||

| + | == Risks & Opportunities == | ||

| + | Some costs or incomes might not be certain (work progress may vary depending on the rain, on the breakdown of a machine...) which would impact the end of work forecast. So, it is important to have a follow up of those risks and opportunities that need to be revised monthly with operational staff in order to avoid bad surprises at some point in time. | ||

| + | |||

| + | Once all the processes are properly set up, the management controller can get down to his main mission which is data analysis, alerting, optimization of expenses and, if necessary, implementing corrective actions to solve deviations. | ||

| + | |||

| + | == Performance management == | ||

| + | The cost controller is responsible for interpreting and evaluating business activity to allow the monitoring of performance. He: | ||

| + | |||

| + | * Determines areas of optimization and helps operational managers in their decision-making | ||

| + | * Support operational staff in their development projects | ||

| + | * Anticipates drifts, alerts operational staff and recommends corrective actions | ||

| + | * Sets up tools for controlling and monitoring actions and measures the effects | ||

| + | |||

| + | For example, one of the main sources of expenditure is labor. The cost controller must analyze hirings and departures on a monthly basis. He must check if all of them have been planned and if not why they are necessary. Labor must be related to the pace of work. For this, the manager must work with the operational teams to determine the remaining work to be done and what manpower is needed for this. In this example it is important for the cost controller to visit the site regularly in order to sensitize the teams if staff are underutilized. | ||

| + | |||

| + | His on-site visits also allow him to check, for example, the rate at which small tools or HQSE equipment is used and whether he needs to review his expenditure budgets. | ||

| + | |||

| + | Making engineers and site managers aware of the expenses and sensitize them about importance of cost management gives momentum to the project and allows everyone to look in the same direction in order to get the project out in the best possible way. | ||

| + | |||

| + | === '''''Monthly cost control meeting''''' === | ||

| + | Goal: | ||

| + | |||

| + | * Analyze figures | ||

| + | * Inform teams | ||

| + | * Learn lessons | ||

| + | |||

| + | It is a time for dialogue, discussion and exchanges between the production manager and his hierarchy. | ||

| + | |||

| + | It results in practical decisions, corrective measure if necessary, and actions follow-up. | ||

Revision as of 05:49, 3 May 2021

The key factors of profitability are managing your income and controlling and forecasting expenses. Therefore, having a good financial control of your project is necessary. It is then recommended to have a cost controller on the project who will monitor de performance of the project and provide the economic and financial indicators to analyze the operational and strategic management of the project.

Role of Financial control[edit | edit source]

Among other things, Financial control main missions are to :

- Monitor project costs and check whether the established objectives have been reached, highlighting any differences with respect to forecasts and identifying, if so, the causes of such deviations, and implementing corrective actions

- Carrie out the reviews of the end-of-site forecasts;

- Performs risk analysis;

- Perform cash analysis and cash forecasts

- Prepare monthly reporting

Steps of Financial control[edit | edit source]

In order to produce the best monitoring, the cost controller must first:

- Read carefully the contract (terms of payment, penalties, bank guarantees, insurances, etc.)

- Understand the milestones and establish a cash-in follow up that will be revised monthly with the operational staff

- Establish a client invoicing follow-up

- Establish a bank guarantee follow-up

- Establish an insurance follow-up

- Understand perfectly the budget allowed to the project and set up a detailed budget breakdown with cost codes (cf Cost Codes section)

- Create processes for Purchase Orders and a subcontractor follow-up (cf Purchase Requisition Procedure section)

- Create a monthly monitoring framework (cf Topsheet section)

Budget Breakdown and Monthly Reporting[edit | edit source]

The production team responsible for the project is committed to forecasting end-of-work expenses that we can call the Objective. The Objective is an intangible reference which represents the common commitment of the production. Every month, the cost controller will compare the reality of expenditure to this initial forecast and present it on a topsheet. This reporting will make it possible to:

- Know the results at the stage and at the end of the work,

- Compare achievements with forecasts,

- Appreciate the future trajectory by assessing the obstacles and risks,

- Decide on actions to influence the trajectory in order to achieve / improve the objectives set

Cost Codes[edit | edit source]

Once he possesses the budget breakdown, the cost controller needs to allocate each category of costs with an analytical code that will help him to allocate all the costs in front of the right budget. The breakdown can be more or less precise, depending on the level of cost analysis desired. An example of the breakdown is given on the right:

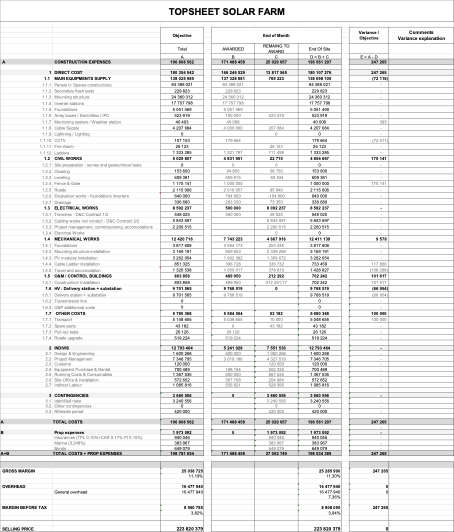

Topsheet[edit | edit source]

The topsheet is the main document of the monthly reporting = it synthetizes the results at the stage and at the end of the works and compares it with the budget.

It gathers all the costs, here is an example of a topsheet for the follow up of a solar project:

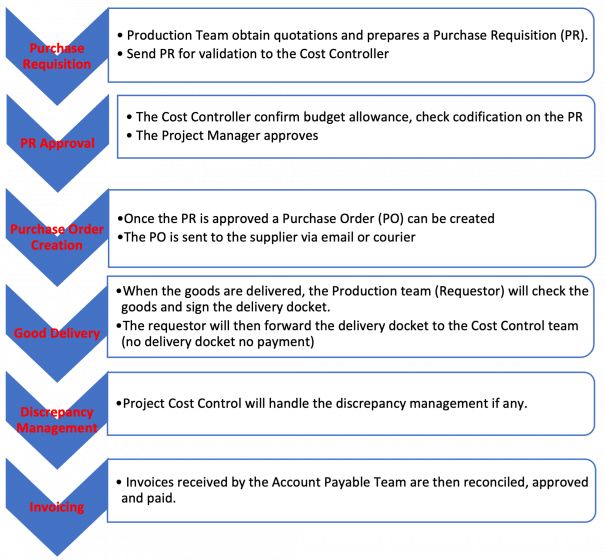

Purchase Requisition Procedure[edit | edit source]

Overall Process Summary[edit | edit source]

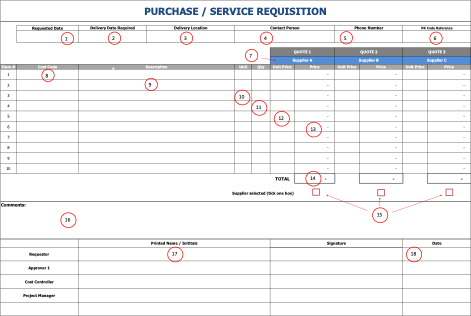

Example of a Purchase Requisition Form[edit | edit source]

Tracking Follow up Example

Risks & Opportunities[edit | edit source]

Some costs or incomes might not be certain (work progress may vary depending on the rain, on the breakdown of a machine...) which would impact the end of work forecast. So, it is important to have a follow up of those risks and opportunities that need to be revised monthly with operational staff in order to avoid bad surprises at some point in time.

Once all the processes are properly set up, the management controller can get down to his main mission which is data analysis, alerting, optimization of expenses and, if necessary, implementing corrective actions to solve deviations.

Performance management[edit | edit source]

The cost controller is responsible for interpreting and evaluating business activity to allow the monitoring of performance. He:

- Determines areas of optimization and helps operational managers in their decision-making

- Support operational staff in their development projects

- Anticipates drifts, alerts operational staff and recommends corrective actions

- Sets up tools for controlling and monitoring actions and measures the effects

For example, one of the main sources of expenditure is labor. The cost controller must analyze hirings and departures on a monthly basis. He must check if all of them have been planned and if not why they are necessary. Labor must be related to the pace of work. For this, the manager must work with the operational teams to determine the remaining work to be done and what manpower is needed for this. In this example it is important for the cost controller to visit the site regularly in order to sensitize the teams if staff are underutilized.

His on-site visits also allow him to check, for example, the rate at which small tools or HQSE equipment is used and whether he needs to review his expenditure budgets.

Making engineers and site managers aware of the expenses and sensitize them about importance of cost management gives momentum to the project and allows everyone to look in the same direction in order to get the project out in the best possible way.

Monthly cost control meeting[edit | edit source]

Goal:

- Analyze figures

- Inform teams

- Learn lessons

It is a time for dialogue, discussion and exchanges between the production manager and his hierarchy.

It results in practical decisions, corrective measure if necessary, and actions follow-up.