Efficiency of PV modules

Concept of PV module efficiency[edit | edit source]

PV Module efficiency is a measurement of how much of the sun’s energy is converted into usable electricity. This is done by capturing the electrical current generated when sunshine interacts with silicon or thin film cells inside a PV module.

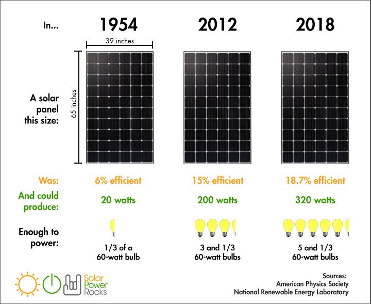

It is measured simply. If a PV Module is 20 percent efficient, that means it’s capable of converting 20 percent of the sunshine hitting it into electricity. In recent times, modules like the Sunpower have high efficiency and can convert up to 23 percent of sunshine falling on their surface. On an average, the efficiency of PV Modules falls between the 15 to 19 percent range.

To put this into actual context, at STC (Standard test conditions), it is assumed that 1,000 watts per square meter (1000 W/m²) of sunlight hits the surface of the PV module. So, if the surface area of a PV module is 1 square meter (1m²), Ideally, we should end up with 1,000 watts of electricity (assuming no losses,100% conversion rate). Now, if the same Module is advertised as producing 100 watts, we’ll end up with an efficiency rating of 10 percent (100 divided by 1000 is 0.1, and 0.1 times 100 percent equals 10 percent).

From the example above, the PV module with 10 percent efficiency translates to the module only being capable of converting 10 percent of all the light that hit it into electricity. A Module with a higher efficiency rating will convert more sunlight into energy.

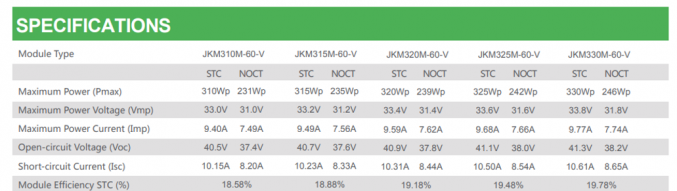

From the picture below, The Jinko modules JKM 310M,315M,320M,325M and 330M all have the same surface area but different power outputs due to the slight differences in their efficiencies.

As stated earlier, the average PV Modules available today average efficiency of around 15 to 19 percent.

General Misconception and Clarifications[edit | edit source]

In some countries for instance, Installers tend to purchase monocrystalline modules over polycrystalline modules, solely because they believe the polycrystalline type is way inferior when compared to the monocrystalline module. How does this compare and what are the major misconceptions ?

Monocrystalline PV Modules have the highest efficiency rates since they are made from the highest-grade silicon, up to 23 Percent. Polycrystalline efficiency is slightly lesser with about 16-19% Efficiency.

How does this matter ?[edit | edit source]

- A 330W monocrystalline and polycrystalline module by Jinko, have a surface area of 1.67m² and 1.94m² respectively. With basic considerations, a 10kW roof installation would cover 50.1 m² and 58.2m² respectively. The polycrystalline module covering 8.1m² more than the monocrystalline module.

- The footprint or surface area covered by the monocrystalline is slightly smaller than polycrystalline.

- It is also true that monocrystalline modules do better in lower light conditions, handles heat better and are made of higher-grade silicon.

Essentially, for large scale installations, installations with limited available space or extreme weather conditions, the difference between polycrystalline and monocrystalline may be big enough to matter. Otherwise, residential and medium scale installation located where there are no shading issues or space constraint can easily interchange or choose any of both technologies.

Cost is an important consideration when it comes down to the overall energy produced. Including the overall cost of installation, racking system, cables and other BOS (Balance of system), a module which is 4% less efficient but 15% cheaper might be a best option. Let us consider this analogy done by Geotherm HVAC

- SolarWorld SunModule 260Wp (poly) = $196 per module ® 0.75 $/Wp

- SolarWorld SunModule 285Wp (mono) = $249 per module ® 0.87 $/Wp

To normalize for wattage, multiply $196 times 285W and divide by 260W. Therefore, the adjusted cost difference is $215 per panel for poly vs. $249 per panel for mono. The monocrystalline module is 16% more expensive, however it do not produce 16% more energy than polycrystalline module, therefore the levelized cost of energy generated by the PV module will be cheaper with polycrystalline PV modules.

For an average home that uses 7,500 kWh annually, the required 18 monocrystalline PV modules would cost $612 more than the less efficient, poly panels.

Calculating efficiency[edit | edit source]

To calculate the efficiency of your Module, just multiply the amount of sunlight that hits the earth’s surface in your area (1000W/m2 at STC) by the area of your Module (Length * Breadth measured in square meters). Divide the maximum wattage on your Module by this number, then multiply it by 100 percent to get an efficiency rating.

However, real world conditions are usually different from the STC, so a typical Module rarely produces its advertised maximum wattage. Firstly, Irradiance is not often reaching 1000W/m2. Secondly, the temperature of the PV Module, is rarely a constant 25°C (the temperature used to determine STC ratings). Most PV Modules are at least 20°C hotter than the ambient temperature. In other words, if the temperature outside is 20°C, your PV Module’s temperature is probably above 40°C.

Summary[edit | edit source]

The choice between monocrystalline and polycrystalline PV Modules is not something that you should lose too much sleep over. It is more important that you choose a good brand of PV Modules. A good brand of PV Module is from a company that invests heavily in the quality of its manufacturing process and invests heavily in its reputation.

References[edit | edit source]

https://www.solar.com/learn/solar-panel-efficiency/

https://www.solarreviews.com/blog/pros-and-cons-of-monocrystalline-vs-polycrystalline-solar-panels

https://powerscout.com/site/how-to-calculate-solar-panel-output

https://www.solar-estimate.org/news/what-solar-module-efficiency-mean-why-it-matters